Elimination and Effective Utilization of Food Loss

Policy for Elimination and Effective Utilization of Food Loss

As part of its crucial responsibilities as a food manufacturer that uses limited food resources, the Kewpie Group has been working to reduce food loss and make effective use of resources.

In recent years, climate change has affected the yield and quality of agricultural products and other raw materials, so it has become increasingly important to reduce food loss. Customers and other stakeholders are also showing growing interest in reducing food loss, and we will continue working to meet their expectations.

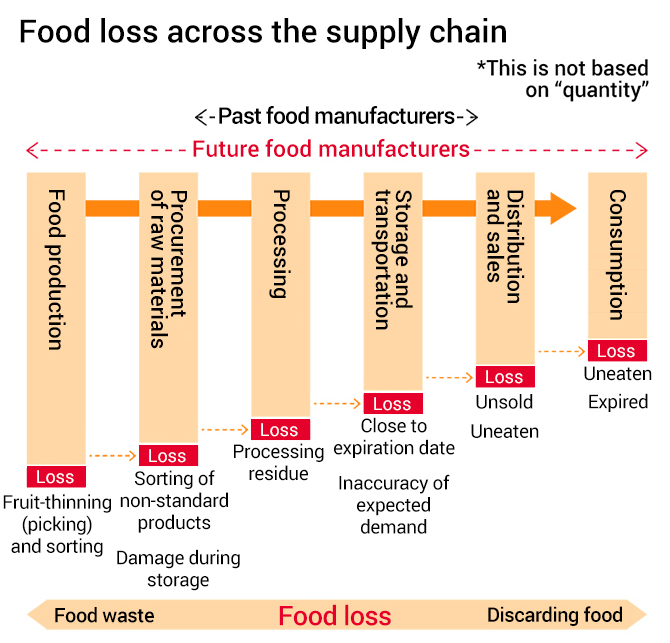

The food loss that occurs at each stage of the supply chain

Response to Food Loss Reduction

At the Kewpie Group, we will continue to implement various measures at each stage of the supply chain and work together within the Group to reduce food loss.

Reducing Food Loss in Manufacturing

The Kewpie Group is working to minimize food loss and waste by arranging production lines efficiently and by innovations in product design.

Deria Foods, which produces a variety of salads and delicatessen foods, is working to minimize food loss and waste. The company has introduced an iterative data-driven system to measure and confirm whether the production weight was appropriate for each manufacturing process, monitor conditions, analyze issues, and make improvements.

Reducing Food Waste after Distribution

The Kewpie Group is working to reduce food loss by extending the best-before dates by making improvements to production methods, containers and packaging, and by changing best-before dates to show the year and month.

In addition, the Salad Club supports the reduction of food loss and waste in growing areas by promoting consumption with bonus package content for consumers peak vegetable harvest time.

| When Started | Target | Details |

|---|---|---|

| Feb 2024 | All Verde Toast Spread series items |

Extended from 13 to 19 months. However, for basil, extended from 11 to 13 months |

| Feb 2024 | Salad Club Shredded Cabbage Mixed Salad - Bonus package content without additional cost to consumers (Kyushu area) | Helps reduce field waste (food loss and waste) at peak production time |

| Feb 2024 | Salad Club Shredded Cabbage - Bonus package content without additional cost to consumers (nationwide) | Helps reduce field waste (food loss and waste) at peak production time |

| Feb 2024 | Salad Club Shredded Lettuce - Bonus package content without additional cost to consumers (Okinawa) | Helps reduce field waste (food loss and waste) at peak production time |

| Feb 2024 | Salad Club Shredded Cabbage Mixed Salad, Broccoli Super Sprouts with Colorful Mixed Salad - Bonus package content without additional cost to consumers (Tokai and Hokuriku areas) | Helps reduce field waste (food loss and waste) at peak production time |

| Dec 2023 | Kewpie 3-Minute Cooking seasoning mixes (3 items) | Extended from 7 to 12 months |

| Sep 2023 | Kewpie Yasashii Kondate (5 items) | Extended from 19 months to 25 months |

| Sep 2023 | Kewpie Aeru Pasta Sauce (8 items) | Extended from 11 to between 12 and 19 months |

| Jun 2023 | Salad Club Cut Lettuce - Bonus package content without additional cost to consumers (all Japan) | Helps reduce field waste (food loss and waste) at peak production time |

| May 2023 | Green Kewpie Dressing (2 items) | Extended from 8 to 10 months |

| Mar 2023 | Salad Club Young Corn | Extended from 19 to 24 months |

| Mar 2023 | Kewpie Deli Fit Mayonnaise (190 kg) | Extended from 60 to 75 days |

| Jan 2023 | Salad Club Shredded Cabbage Mixed Salad, Broccoli Super Sprouts with Colorful Mixed Salad - Bonus package content without additional cost to consumers (Tokai and Hokuriku areas) | Helps reduce field waste (food loss and waste) at peak production time |

| Jan 2023 | Kewpie Iron Fortified Soft Osembei Rice Crackers | Extended from 6 months to 12 months |

| Sep 2022 | All Kewpie Aeru Pasta Sauce series items | Changed to year/month display Best-before dates extended |

| Sep 2022 | 31 items in Kewpie Yasashii Kondate nursing care foods series | Best-before dates extended to 25 months |

| Jun 2022 | Increased volume of Salad Club's Cut Lettuce | Maintaining production systems and supporting reduction of production food loss |

| Mar 2022 | Salad Club Cabbage for Frying: Cut vegetables for heating | Achieved the industry’s longest shelf life of 7 days (processing day plus 7 days) |

| Feb 2022 | Kewpie Three-minute Cooking soup ingredients of Yasai wo Tabeyou (Let's eat vegetables!) series | Changed to year/month display Best-before date extended from 12 to 13 months |

| 2022 | Potato salad and other delicatessen items | Extended shelf life by Cold Pressed Fresh Manufacturing Method®*

* Food is processed at low temperature and high pressure to retain original texture and color of ingredients and extend shelf life while preserving flavor |

| Apr 2019 | Salad Club Shredded Cabbage | Expiry date extended by one day (processing date + 5 days) |

| Mar 2019 | Part of Salad Club Sozai Pouch (ingredients pouch) series products |

Best-before dates extended Changed from year/month/date to year/month display |

Reduction in Product Waste

The main causes of product waste are the gap between production based on demand forecasts and actual sales and returns due to unsold products at the distribution stage. With the cooperation of each company and department, we are working to solve these issues by actively donating to food banks.

Production-Sales-Logistics Coordination to Improve Accuracy of Supply-Demand Management

Since 2015, related departments hold a working group every month. At this working group, we focus on "product inventory" and discuss various issues and solutions surrounding production to distribution. Thanks to such monthly engagement, we have seen a consistent rise in the awareness of food loss within the company.

Efforts to Reduce Product Returns in Collaboration with Business Partners

We work with distributors and wholesalers in the Kanto area to reduce the amount of waste due to products not being sold. By reviewing the product sales trends at each store and optimizing product delivery, we have achieved zero returns.

Currently, we are expanding this initiative horizontally and working to reduce product waste throughout the supply chain while promoting internal and external cooperation.

Recipes to Reduce Food Waste

On our Totte-Oki Recipe (best recipes) website, which introduces various food preparation menus, since 2019 we have been introducing recipes developed at Tokyo Kasei University to make use of cabbage cores, lettuce outer leaves, and broccoli stalks.

Three-minute Cooking, a Kewpie-sponsored television program, give viewers timely and easy, convenient, daily menu recipe suggestions. As consumers' environmental responsibility has become a daily interest, we are also incorporate the concept into our programs.

We introduce recipes that reduce environmental impact and also can be easily incorporated into daily cooking. We proactively introduce techniques to use ingredients efficiently and without waste, and ideas that lead to energy conservation, and provide opportunities to be a green consumer.

Logo

Promoting Effective Utilization

The Kewpie Group is working on various initiatives in collaboration with stakeholders to make effective use of food resources.

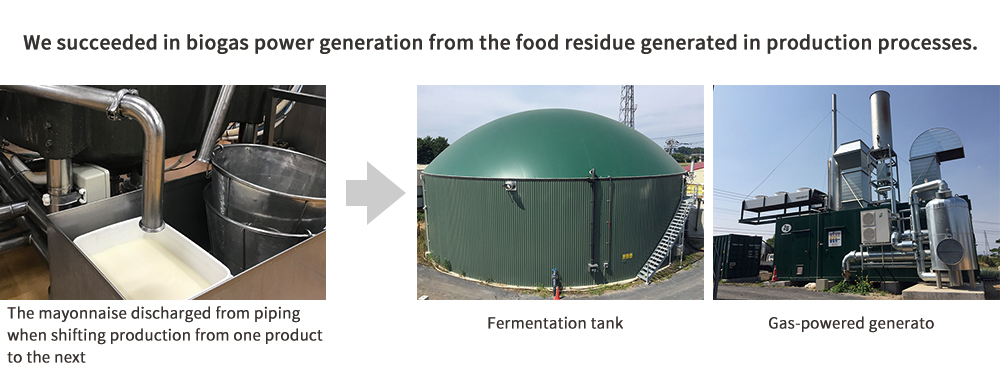

Biogas Power Generation from Food Waste*

The process of manufacturing a wide variety of mayonnaise products generates food residue, as in the case of mayonnaise discharged from piping when shifting production from one product to the next. We at the Kewpie Group have succeeded in biogas power generation from the food residue generated in production processes.

This initiative is being implemented at Kewpie's Goka Plant, Nakagawara Plant, Izumisano Plant, Kobe Plant, and Kpack Co., Ltd., a group company.

*Our biogas power generation is a way to generate electricity from biogas produced through methane fermentation from food waste and livestock waste from pig farms.

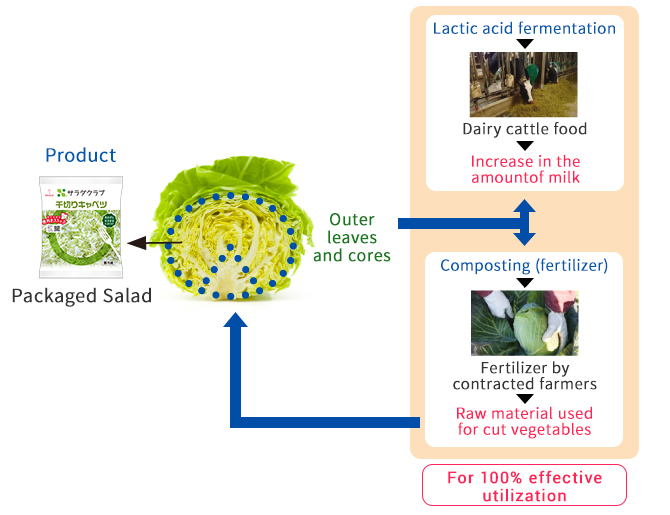

Unused Portions of Vegetables

The Kewpie Group is engaged in finding ways to make effective use of the unused parts of vegetables used in the processing of salads and delicatessen foods. These unused portions include the core, calyx, outer leaves, and peel.

Unused Portions of Leafy Vegetables

In FY2017, the cut vegetables production plant, Green Message, had success in converting leafy vegetables, such as cabbage and lettuce, into stock feed, something that had previously been considered difficult to do on a commercial scale. In a joint research project between Kewpie Corporation and Tokyo University of Agriculture and Technology, it was reported that dairy cattle that were fed this feed produced greater yields of milk.

Salad Club Co., Ltd. takes the unused parts of vegetables such as outer leaves and cores generated when producing packaged salads at its seven directly operated plants and turns them into feed and compost to be utilized by contracted farms and other customers.

Effective use of unused parts of vegetables (e.g. cabbage)

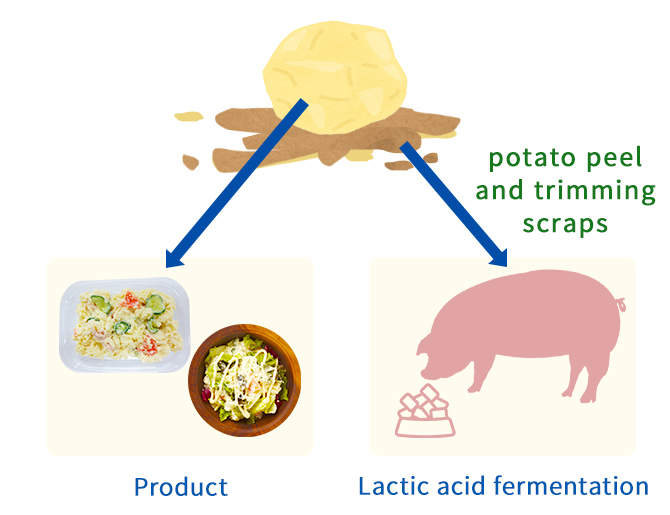

Unused Portions of Potatoes

At Potato Delica Co., Ltd. and the Shunsai Deli Co., Ltd. Akishima Plant of the Deria Foods Group, potato peels and trimming scraps from the production of potato salads are liquified using special technologies to produce feed for pigs.

This technology is connected with production and stable logistics of safe domestic feed, which is a challenge in the pig farming industry, and also helps create a recycling-oriented society that makes use of food residue.

Unused Portions of Potatoes

100% Effective Use of Eggs

The Kewpie Group products a variety of processed egg products besides mayonnaise. 10% of the eggs produced in Japan are used by the Kewpie Group.

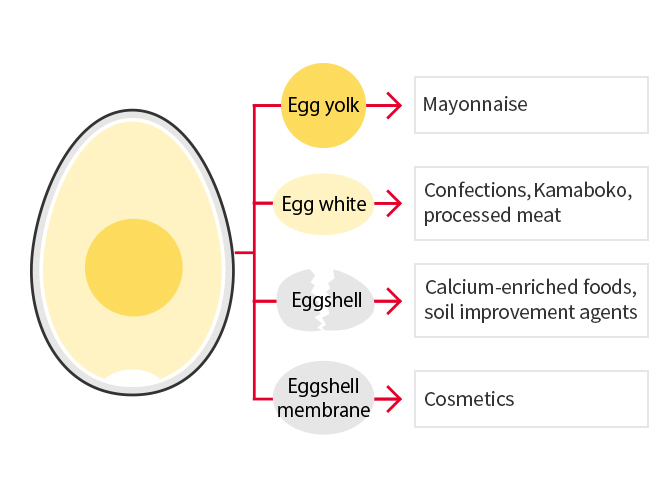

Kewpie Mayonnaise is made with the egg yolks, and the whites are used as food ingredients in processed seafood paste products such as kamaboko, and confectionery products such as cakes.

The approximately 28,000 tonnes of eggshells generated annually are also put to effective use in soil improvement agents, an additive for calcium-enriched foods, and other products, with 100% of eggshells being recycled. We are also working on advanced uses for eggshell membranes, such as in cosmetic products.

Effective use of eggs

Egg Shells Fortify Rice and Strengthen Human Bones

The Kewpie Group is conducting a joint research on the value of egg shells as fertilizers with Professor Yoshimasa Tsujii and Professor Taku Kato from the Faculty of Applied Biosciences at the Tokyo University of Agriculture. So far, we have been able to determine that adding egg shell fertilizers to rice paddies reduces the effects of unseasonal weather, such as extreme heat, on the rice. This improves harvest yield and enhances rice quality. Since rice makes up most of Japan's crop acreage,* we are hopeful that egg shells can be effectively utilized in the future, not only by the Kewpie Group but also across the whole country.

Furthermore, a separate joint study conducted with the National Institute of Nutrition in Hanoi, Vietnam revealed that calcium from egg shells (biomaterial consisting mainly of calcium carbonate from egg shells finely ground for eating purposes) improves bone density in humans. This shows that egg shells can contribute to resolving the global issue of osteoporosis (bone weakness) that is emerging as the population ages. In Vietnam, we are currently selling a nutritional supplement product that contains egg shell calcium while also working to raise awareness and propose the solution to schools and medical facilities. In this way, we are striving to improve children's physical build and resolve the issue of osteoporosis among the elderly.

*Based on the 2018 statistics from the Ministry of Agriculture, Forestry and Fisheries on the aggregated planted (growing) area of agricultural crops and utilization rate of cultivated land

Message

Our Challenge Going Forward is to Uncover the Full Potential of Egg Shells.

We believe calcium, which is the main component of egg shells, not only strengthens each of the cells in a plant but also facilitates various bioactivities within the cells. Meanwhile, global climate change is triggering extreme heat to such extents that even humans are having a hard time coping. As one of its physiological actions, calcium plays an important role in filling rice in their hulls during times of high-temperature stress. Egg shells contain a large amount of calcium, and in the context of global climate change they can be seen an agricultural resource that can help protect rice from summer fatigue and provide a stable supply of good-tasting rice.

Professor Taku Kato

Laboratory of Soil Fertility and Fertilizers, Department of Agricultural Chemistry, Faculty of Applied Biosciences, Tokyo University of Agriculture

Function of Eggshell Membranes

Using methods developed by Kewpie, we successfully separated eggshell membranes from egg shells. We discovered that water soluble eggshell membranes can increase type III collagen, which makes skin more smooth and supple. As such, we have been utilizing it as a raw ingredient for cosmetics since 1991.

Calcium Fertilizer Born from Egg Shells and Vinegar

Kewpie Jyozo Co., Ltd. developed and distributes a calcium fertilizer called "Yokatsusu," which is made by dissolving egg shells in vinegar.

Regularly spraying the fertilizer on the leaves of vegetables, fruits and flowers prevents calcium deficiency and allows the plants to grow healthily.

Since the product is derived from food products, it is both human and environmentally friendly and can be used without concern.

History of Utilizing Egg Shells

- 1956: Began sun-drying egg shells and selling them to farms as soil conditioner

- 1969: Installed equipment for crushing and drying egg shells (former Sengawa Factory)

- 1981: Began selling egg shells as a source of calcium for food products (achieved by developing membrane-removal technology)

- 1991: Processed eggshell membranes and began selling them as a raw ingredient for cosmetics

- 2007: Began selling egg shells as a raw material for construction materials and regular commodities (wallpaper, tires, etc.)

- 2012: Began research on rice grown using egg shell fertilizers

- 2017: Began selling Egg Shell Calcium Sauce as a nutritional supplement product in Vietnam

- 2019: Our egg shell initiatives won the "3Rs (Reduce, Reuse, and Recycle) Promotion Merit Awards" for the Minister of Agriculture, Forestry and Fisheries Award

- 2020: Our egg shell initiatives won the "Food Industry Mottainai (Reducing Wastefulness) Awards" for the Ministry of Agriculture, Forestry and Fisheries' Food Industry Affairs Bureau's Top Award

- 2021: The video "Effective Use of Eggs" won the "Green Food System Promotion Award" at the Sustainer Award 2021.