A Passion for Quality

Developing People to Assure Quality

Quality is assured by people. We create forums for learning and information-sharing in the aim of enhancing quality.

Monodukuri Gakko

The quality course at our Monodukuri Gakko (food production school) provides a learning forum for managers across all divisions involved in the product-making process. They learn about quality at all levels, from the basics of product quality management to advanced applications. After completing the quality course, managers return to their divisions to train their own staff, passing on the knowledge and techniques they have acquired. Monodukuri Gakko trains core personnel who share their passion for quality with their co-workers to raise quality throughout the entire Kewpie Group.

Monodukuri Gakko Subjects

Safety Principles

Quality techniques and knowledge relating to microbes, analysis, etc.

Food Security Principles

Understanding of quality rules, including laws, regulations, and in-house procedures.

Sources of Reliability

Managers study past cases to learn approaches that form the foundations of quality.

Wakuwaku Award

What is the Wakuwaku Award?

The Kewpie Group conducts Wakuwaku Activities as quality improvement activities that bring a smile to customers and employees.

Guided by the slogans of "Global", "Cooperation and Creativity", and "Empathy (Praise)", we hold the Wakuwaku Award to share and horizontally develop the Wakuwaku Activities of teams selected from all Kewpie Group companies in Japan and overseas, and aim to be a corporation that is "contributing to the food culture and health of the world."

Creating Systems to Underpin Quality

We have introduced systems to maintain and improve Group quality levels by gaining international certification from third parties.

Third-Party Food Safety Certification

All Kewpie Group production facilities have been certified by the Global Food Safety Initiative (GFSI).

Regular reviews by an external body provide an objective perspective on assuring and improving quality, enabling us to continually maintain and raise quality levels.

GFSI Certification

GFSI was established in May 2000 to provide food safety certification. GFSI certification includes certification against the FSSC22000 standard developed in the Netherlands and the SQF standard developed in the US.

Quality Improvement Techniques

We research and introduce the latest production techniques in our efforts to improve quality.

Analytical Techniques

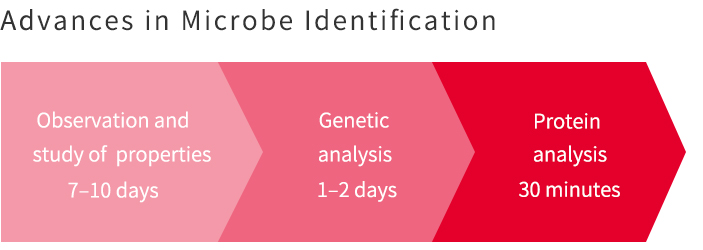

Techniques to identify microbe varieties contained in foods have advanced rapidly in recent years.

Identification of Microbes Contained in Foods

Previously microbes were isolated from foods and cultured before microscopic observation to study their properties, and identification took 7–10 days. The emergence of genetic methods reduced this to 1–2 days, and now the use of protein measurement techniques has shrunk the identification timeframe to just 30 minutes.

As well as proactively introducing effective methods as techniques have progressed, we have partnered with external bodies to develop new technologies.