Environmental Management

- Policy for Environmental Management

- Kewpie Group Environmental Policy

- Environmental Management Promotion Structure

- Environmental Management Systems

- Compliance with Environmental Legislation

- Environmental Audit

- Environmental Impact of Business Activities

- Consideration for Local Environments

- Environmental Communication

Policy for Environmental Management

The Kewpie Group’s business is supported by the bounty of nature. However, environmental issues such as global warming, marine pollution caused by plastic, and loss of biodiversity are becoming more serious and are having a major impact on corporate activities. For many years, the Kewpie Group has made efforts to reduce the environmental impact of its business activities based on our "Quality-First" principle.

Environmental Vision

We formulated the Kewpie Group Environmental Vision 2050 in line with our 11th Medium-term Business Plan, which begins in 2025. We will promote environmental activities focused on realizing a decarbonized society, creating a recycling-oriented society, and preserving biodiversity, thereby contributing to the realization of a sustainable society.

Kewpie Group Environmental Policy

The Kewpie Group Environmental Policy was established* in December 1998 in response to growing awareness of environmental conservation in Japan and overseas. We will promote initiatives in conjunction with the Kewpie Group Basic Sustainability Policy.

Kewpie Group

Environmental Policy

We strive to be environmentally friendly in our business activities throughout the value chain, from product design and raw material procurement to production, sales, and consumption.

- 1.We strive to conserve resources, save energy, reduce waste, promote recycling and develop recycling technologies.

- 2.We promote the development of environmentally conscious products and the optimization of containers and packages.

- 3.We voluntarily set standards and strive to preserve the environment, abide by legal regulations, and furthermore, prepare and enhance an environmental management structure that allows us to respond to social demands.

Adopted 1998, revised 2022

Material Issues and Targets

The Kewpie Group has established indicators (sustainability targets) to guide its efforts to address the material issues of "effective use and recycling of resources", "deal with climate change", and "conservation of biodiversity" as part of its global environmental efforts.

Environmental Management Promotion Structure

The Kewpie Group has established the Sustainability Committee chaired by the director in charge of sustainability. Regarding the environment, subcommittees and collaborative projects have been established for each theme to address the material issues for sustainability, and efforts have been made to ensure that responses to these issues take root throughout the Group.

Environmental Management Systems

To provide basic tools for operating a plan-do-check-act cycle for environmental conservation activities, the Kewpie Group has introduced systems based on ISO14001 or its own equivalent standards at each of its facilities.

ISO14001 Certification Acquisition Status

24 of the 71 Group production locations in Japan have obtained ISO14001 certification. (As of the end of November 2023)

Compliance with Environmental Legislation

Each location of the Kewpie Group complies with environment-related regulations and operates under its own standards.

* In FY2023, there were no accidents or violations of related regulations.

Environmental Audit

The Kewpie Group has its criteria for legal compliance, development of management and promotion procedures, and facility management standards. We conduct regular internal audits based on the above criteria and promote environmental conservation activities accordingly. Furthermore, we conduct standard-based audit by external institutions at locations with ISO14001 certification to ensure a proper compliance to those standards.

Environmental Impact of Business Activities

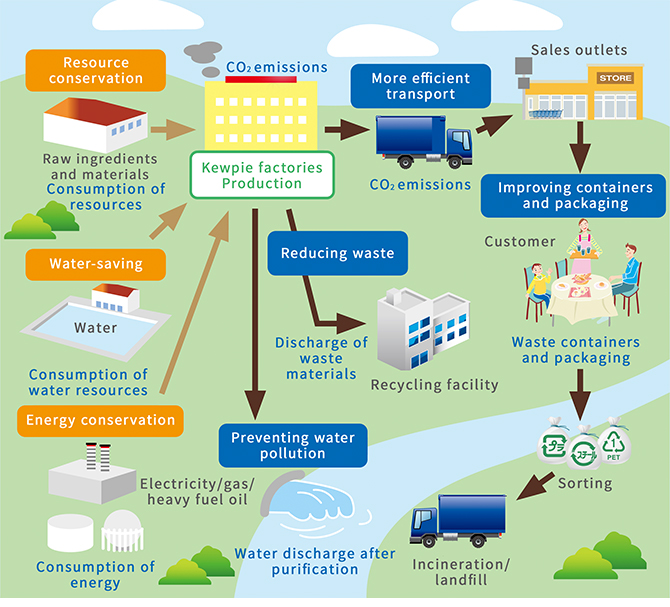

In the production process, we consume natural resources, such as raw materials, ingredients, water, and energy, including electricity, gas, and heavy oil that cause industrial waste products, wastewater, and CO2 emissions. In addition, we recognize the environmental burden due to product transportation and consumer waste, such as disposed containers and packaging.

Therefore, we recognize that it is our responsibility to identify the environmental burden caused by our business activities and product development, procurement of raw materials, production, selling, and distribution. Based on the recognition, we strive to promote environmental conservation activities on energy and resource conservation, waste reduction, improvement in containers and packaging, streamlining transportation, and pollution control.

Energy and Material Flows in Kewpie Group Production Divisions

We strive to utilize resources effectively throughout the value chain.

Energy and Material Flows in Kewpie Group Production Divisions (Fiscal 2023)

Input

| Energy use | Electricity purchased | 1,925,000GJ (205,193,000kWh) |

|---|---|---|

| Fuel*1 | 1,048,000GJ | |

| Total energy | 2,973,000GJ | |

| Water use | Water (groundwater, piped water) | 7,367,000m3 |

Output

| Atmospheric emissions | CO2 | 149.900 Tons |

|---|---|---|

| NOx | 33.6 Tons | |

| SOx | 6.7 Tons | |

| Emissions to waterways*2 | Emissions | 5,879,000 m3 |

| Emissions of waste | Volume of waste (recycling rate) | 33,500 Tons(97.2%) |

*1: Including fuel used to generate electricity

*2: Including rivers and public sewer systems

Applicable facilities: Kewpie Group factories

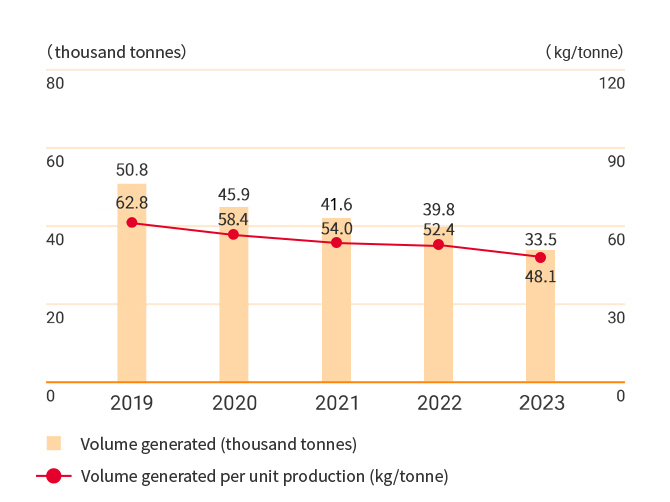

Reduction of Generated Waste

Waste generation reduction targets

- Total volume generated and output per unit of production volume Year-on-year reduction

The main waste generated from Kewpie Group plants includes food loss and waste from manufacturing processes and plastic waste as packaging material losses, as well as post-treatment sludge at wastewater treatment facilities.

At the Kewpie Group, our top priority is to reduce the generation of waste by improving yields in manufacturing processes and improving containers and packaging.

In addition, we are working to achieve a 100% recycling rate for waste generated at factories (meaning zero basic incineration or disposal in landfill), by using eggshells as fertilizer, in-house recycling of food loss and waste including unused vegetable parts (as compost and animal feed), and outsourcing the recycling of waste (as compost).

Our recycling rate in FY2023 was 97.2%. Also, 28 of the Group's 71 production sites have achieved a 100% recycling rate.

Volume of waste generated**

Figures are for Kewpie Group production plants

*Excludes bi-products that are recycled within the Group, e.g. eggshell powders.

*The significant decline can be attributed to the partial disposal of the salad and delicatessen sector by sale.

Consideration for Local Environments

Kewpie Group production facility operations consider nearby residents and local environments.

Preventing Water Pollution

We have set voluntary water quality standards for discharge of water after purification in wastewater treatment facilities, and comply with standards applying in each region. We also ensure that tanks for liquid ingredients, fuel, etc. are leak-proof, and conduct exercises to prepare for the unlikely eventuality of such substances seeping into public water areas or groundwater.

Preventing Atmospheric Pollution

Operation of equipment such as boilers and co-generation systems is managed appropriately, and we carry out regular checks, maintenance, and smoke measurement. We are progressively shifting to fuels for boilers, etc. that emit low levels of soot, dust, and sulfur oxide.

Controlling Noise and Odors

We deal with odors arising from wastewater treatment and cooking by improving processes and installing deodorizing equipment. To prevent noise, we install soundproof walls, conduct noise assessments when introducing new equipment, and issue instructions and guidelines to employees and contractors.

Environmental Communication

All business activities at the Kewpie Group have never been feasible without the existence of rich nature. To ensure a sustainable society in the future, we provide our stakeholders with the information of our efforts to identify negative environmental impacts caused by our business activities, reduce its burden, and conserve the environment.

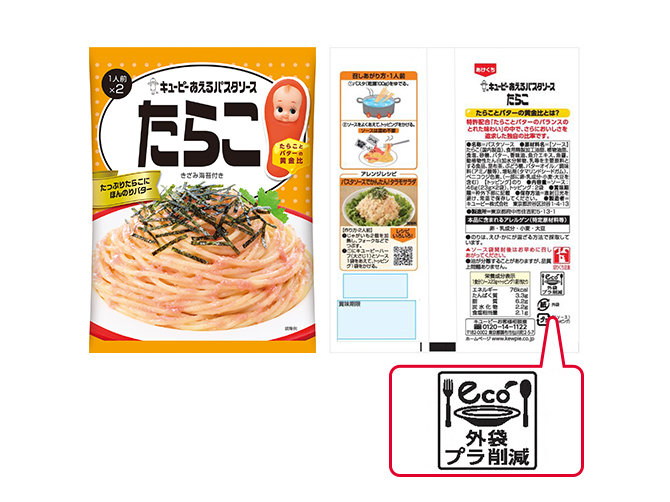

Kewpie Group Eco Label

The proprietary Kewpie Group Eco Label will be implemented from February 2024. Having established environmentally friendly standards on container packaging, Kewpie assigns the Kewpie Group Eco Label to products meeting these standards to easily convey to customers that Kewpie products are environmentally friendly.

Example

Design Intention

With an emphasis on the aspiration for "love around the kitchen table," the Kewpie Group aims to resolve various problems with "great taste, empathy, and uniqueness." As part of these efforts, we incorporated the concept of “love around the kitchen table” into the Kewpie Group Eco Label design for environmentally friendly products.

The Kewpie Group Label Mark design includes a plate, spoon, and fork, which are essential aspects of the dining table, with the Eco logo positioned in the center to convey environmental friendliness. The letter "o" is accented with a leaf.

Kewpie Eco Label Criteria

| Details | Eco Label Criteria |

|---|---|

| Reduced plastic usage | Reduced amount of plastic used by 5% or more (using 2018 as the base year) |

| Reuse of plastic | Recycled plastic materials comprise 25% or more of total plastic by weight |

| Biomass plastic | Biomass plastic comprises 10% or more of plastic used, by weight |

Labeling Example

Environmental Education

At the Kewpie Group, we raise employees' awareness towards environmental conservation and conduct environmental education to put their awareness into practice.

Our efforts also include seminars specifically designed for environment-related operations among departments within the Group, as well as supervisions on wastewater and waste management on a regular basis.

Furthermore, at each location, we offer general education regarding environmental issues and hold drills to prepare for environment-related emergencies.